- 中文

- |

- English

- |

- Русский язык

- |

- Español

- |

- Tiếng Việt Nam

- |

- Türkçe

Established in 1957 and officially listed on the Shenzhen Stock Exchange (stock code: 000821) in June 1998, J.S. Machine is an international manufacturing enterprise that integrates research and development, production, sales, and service.

Our main business is intelligent high-end manufacturing equipment, leading in the two sub-sectors of photovoltaic and paper packaging equipment, providing integrated, personalized, automated, and intelligent factory solutions. At the same time, we seize the opportunity of China's vigorous development of new energy, assist in the landing of "dual carbon" goals, and vigorously develop photovoltaic, lithium battery equipment manufacturing, and system solutions.

Starting inland, rooted in coastal areas, and globally deployed, we provide quality products and services to more than 60 countries and regions worldwide.

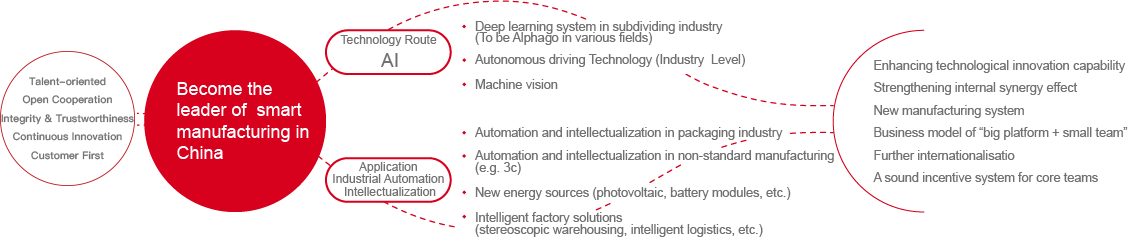

By strictly focusing on the mission of “Empower Smart China, Build World Brand”, while taking “Human Oriented, Continuous Innovation, Honesty and Integrity, Customer First, Open Mind and Collaboration” as our core value concept, we are actively engaged in technological innovation and intelligent manufacturing, internationalized regional expansion, new industrialization and strengthening internal synergy. We are committed to be the leader of Chinese intelligent equipment manufacturing!

Start the platform with a concentric dream, build up ecology with empowering each other, and prosper the industry with smart manufacturing.

Through endogenous development and extensive acquisition, the company has formed the industrial automation layout with the core of “packaging automation +3C automation + photovoltaic automation”, which covers more than ten industries, including production line automation, intelligent logistics, intelligent storage, and has maintained rapid development momentum.

At present, the company has designed and implemented more than ten industrial automation solutions, with mature cross-industry development experience.

Through the group integration management of the company, we strengthened cooperation and promoted the mutual promotion and development of the company’s business.

As an innovator of China’s intelligent equipment manufacturing, J.S. Machine will help China make the smart era and create a smart equipment manufacturing ecosystem with global influence.

{{item.content}}