- 中文

- |

- English

- |

- Русский язык

- |

- Español

- |

- Tiếng Việt Nam

- |

- Türkçe

Huizhou AImega Precision Co., Ltd. founded in 2001, is a wholly owned subsidiary of J.S. Machine (stock code: 000821).

Located in Huizhou Huicheng District, the company now has over 650 employees among whom more than 150 are R&D personnel.

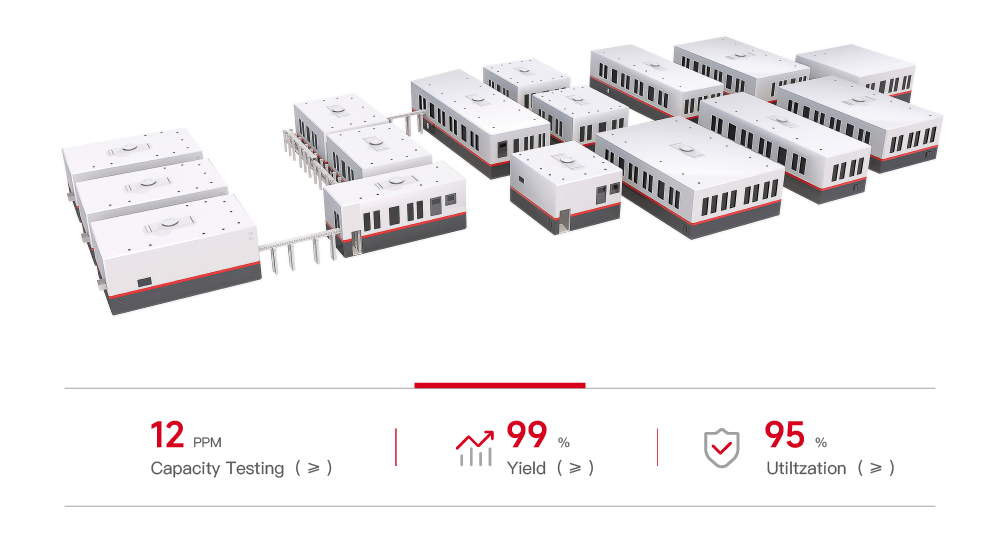

Specialized in the R&D, manufacturing, sales, and service of automation equipment, we provide efficient automated solutions to clients in the lithium battery, power battery, 3C, and logistics industries.

Star Products